A specialized manufacturer of high-quality and high-complexity Toolings for the Aerospace industry, Wah Son produces to your exact specifications a full range of products including:

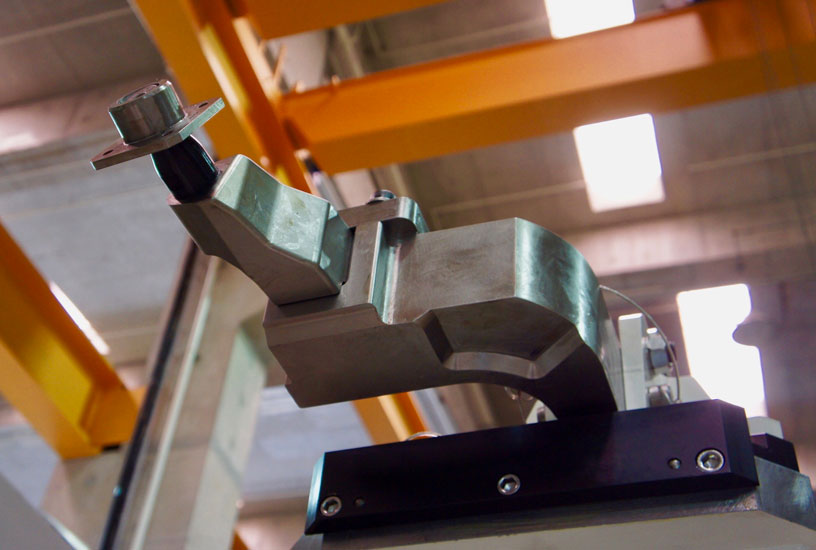

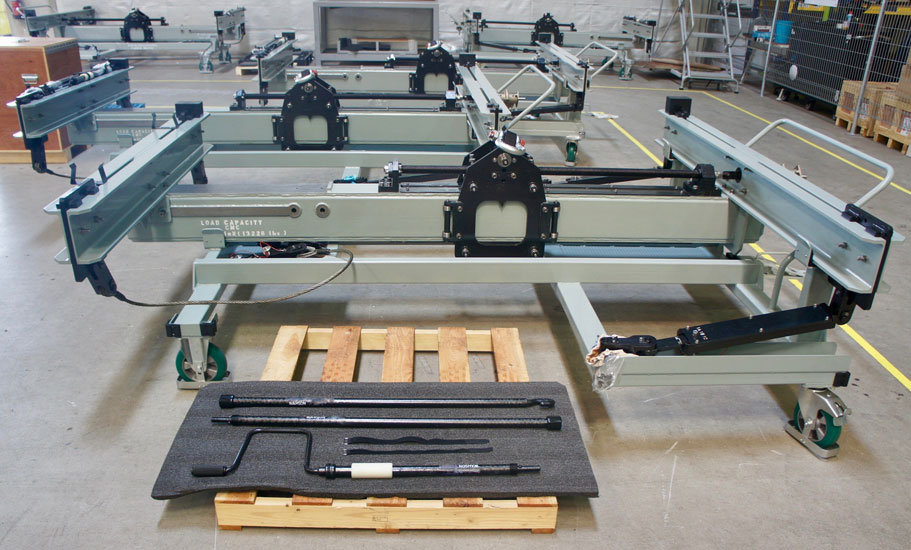

- Assembly & Disassembly Toolings for Engine & Modules

- Component Repair Toolings

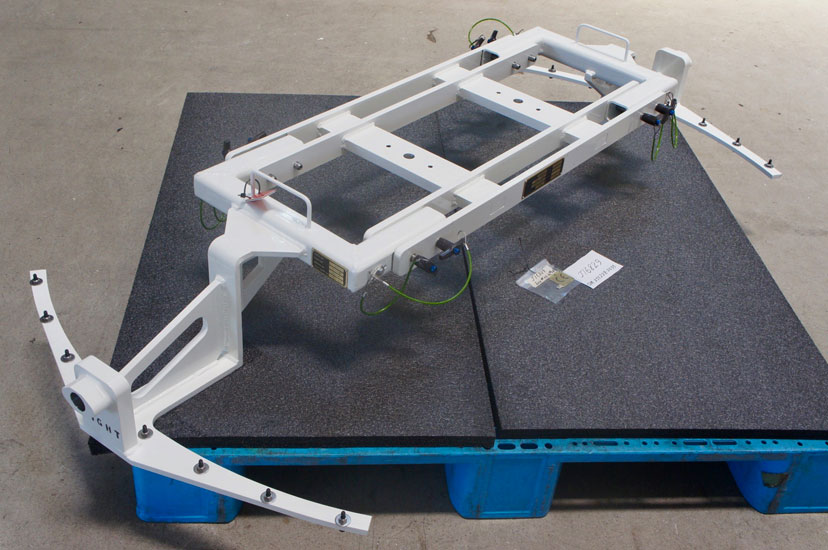

- Engine Transportation Stand/Ground Support Equipment

- Engine Test Equipment

- Fabrication Fixtures

- Inspection Fixtures

- Lifting Devices and Equipment

- Line Maintenance Toolings

- Machining Fixtures

- Passenger-To- Freight Conversion Toolings

Our core capabilities also include:

- Manufacturing of precision Tools, Jigs, Fixtures, Structural Equipment and GSE for the Aerospace MRO sector

- Machining of medium-to- large, high complexity and tolerance parts for various Precision Engineering industrial sectors

GE Aviation, RHINESTAHL Customer Tooling Solutions

- Manufacturing of large, high-complexity and high-tolerance tools & GSE for various GE and CFMI engine programs.

- Approved Supplier & Designated Supplier Quality Representative ("DSQR")

Rolls-Royce plc, Singapore Aero Engine Services Pte Ltd (SAESL)

- Manufacturing, repairing and calibration of wide spectrum of tools & GSE for Rolls-Royce Singapore Engine Production and Test facilities

- Design & Manufacturing of repair tools and gantry tools for engine strip, repair, inspection and of Trent family of engines

- Rolls-Royce SABRe-approved Tooling Supplier

Pratt & Whitney, Collins Aerospace

- Design & Manufacturing of full suite of repair and inspection fixtures for Pratt & Whitney’s Singapore-based subsidiaries and joint ventures

- Manufacturing of repair tools and assembly jigs for various Airbus & Boeing nacelle systems

- Collins Aerospace Licensed Provider of Program Aircraft MRO Tooling

Wah Son Engineering Pte Ltd’s commitment to quality improvement is shared by each team member within the company. Every team member is dedicated to product safety and customer satisfaction by satisfying our customers through:

- Consistently meeting or exceeding our customer’s expectations for product safety, quality and service performance,

- Complying with regulatory, safety and quality system requirements,

- Continually improving our processes and services to create value,

- Listening to our customers and meeting their needs,

- Recognizing product quality and safety as a prime consideration at all times.

Quality Focus

- Focused in serving the Aerospace Tooling market

- "Do-it-right-first-time" mindset with attention to details

- Ability to engineer to precise tolerances at component and assembly levels

Customer Dedication

- Deliver personalized services to customers

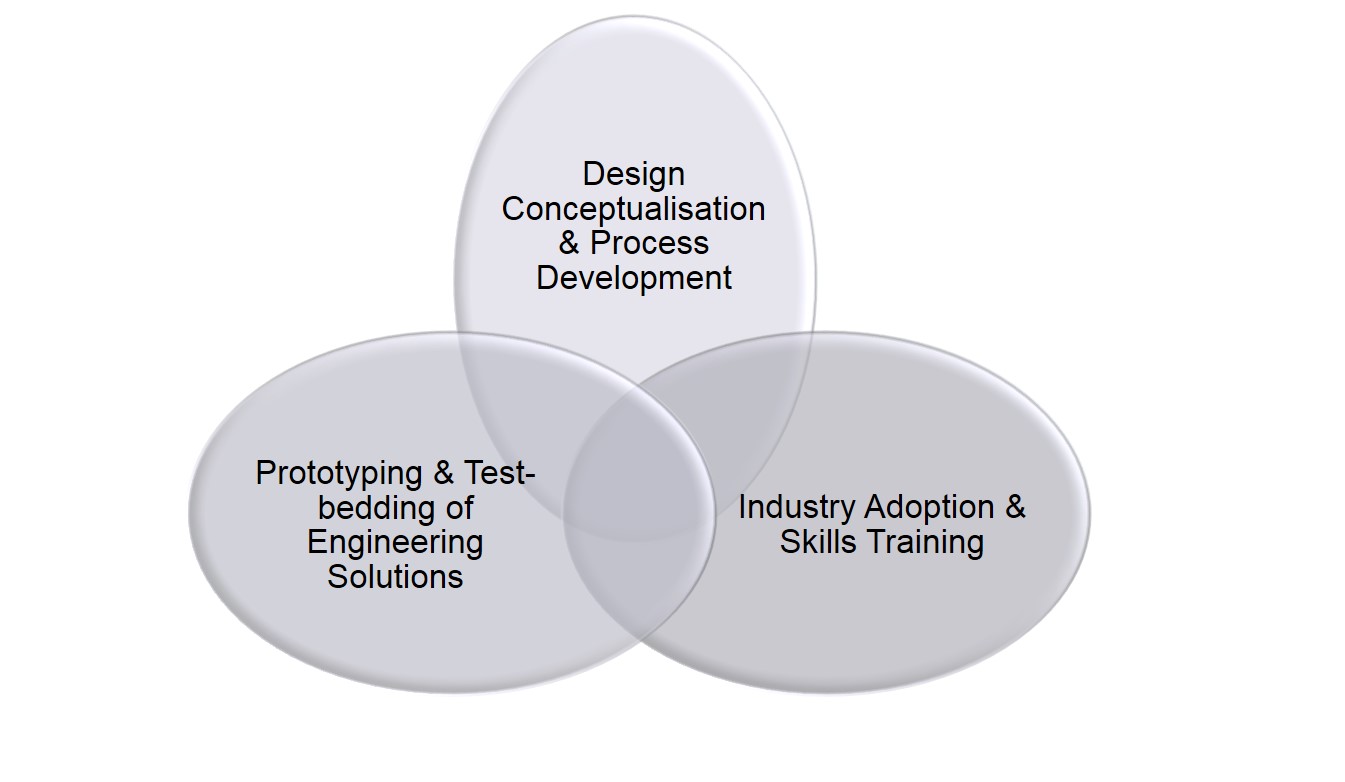

- Provide one-stop solution from design, modification and manufacturing, to repair & maintenance of aerospace tooling

- Supported leading global customers for more than 18 years

Prompt Delivery & Fair Pricing

- Nimble setup with high operating efficiencies

- Close collaboration with specialist sub-contractors to provide seamless and timely support to customers

- Track record of delivering quality tools in AOG scenarios

- Stringent quality system to manage sub-tier suppliers